MOLD DESIGN & MANUFACTURE

2 color mold, cap mold, container mold, garden mold

Two color fliptop cap mold

# double color cap mold # Bi- color fliptop cap mold # two color shampoo cap mold # two shot injection cap mould

Two color fliptop cap information

- Product Name: two color shampoo cap

- Material: PP + PP

- Product weight: 7g

- Product size: 53x70x28mm

Two color fliptop cap mould information

- Mould cavities: 8 cavities

- Mould steel: 2344 steel with HRC 45-48

- Mould injection system: 16 tips Hot runner

- Suitable injection machine: two color machine 280T

- Mould size: 742x895x586mm

- Mould weight: 1048KG

Cosmetic Jar Mold

Product information

- Part Name: 150g Cream Jar / Cosmetic Jar

- Part Material: PP

- Part Weight: 14g

- Part Size: Diameter 70mm, Height 69mm

Mould information:

- Mould cavities: 4 cavities

- Mould injection system: 4 tip Yudo hot runner

- Mould steel: S136 steel with Hardness HRC 45-48

- Suitable injection machine: 250T

- Cycle time: 20s

Flower pot mould

Disposable flower pots

Part Name: disposable flower pots

Part Material: PP

Part Weight: 41.9g / 31.8g

Part Size:

Big size: top dia. 136mm, bottom dia. 103mm, H125mm

Small Size: top dia. 120mm, bottom dia. 84mm, H113mm

Order Flower pot mold from China

Send inquiry to Elaine, WhatsApp +86 18257612359, Email: weramold@163.com

Mould information:

Mould cavities: 2 cavities

Mould injection system: 2 tip hot runner

Mould steel: S136 steel with Hardness HRC 45-48

Suitable injection machine: 250T

Cycle time: 10s

Fliptop cap Mould

Shampoo Bottle with fliptop cap

Part Name: Fliptop cap for shampoo

Part Material: PP

Part Size: 59.6* 70*27.52mm (open size)

Part Weight: 7.8g

–

Mould information:

Mould cavities: 4 cavities

Mould injection system: 4 tip hot runner

Mould steel: S136 steel with Hardness HRC 45-48

Suitable injection machine: 160T

Cycle time: 15s

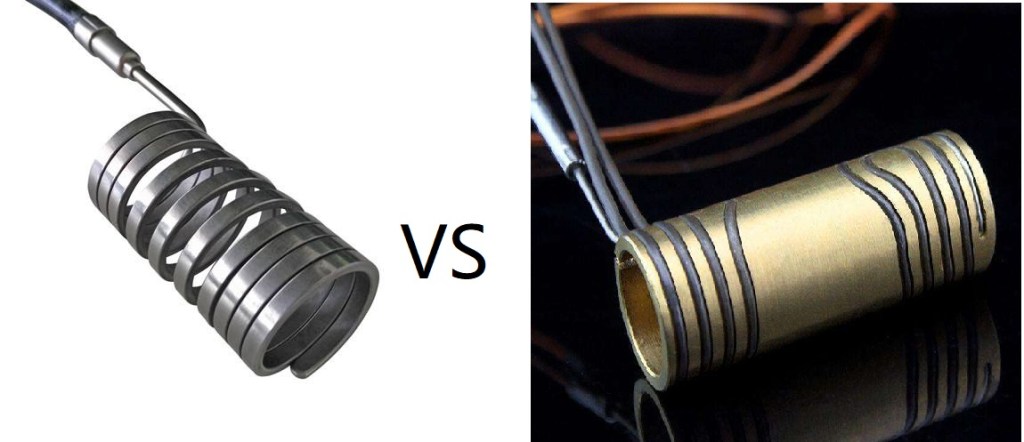

Hot runner heat coil types

Hot runner system is more and more widely apply into different kind injection mold. Heater system also upgrade day by day.

This article just want to share some personal idea of the difference between two types heat coil.

- spring type heat coil It is an old type heat coil which widely use in market, you can find it easily in shops. Advantage: easy to find, easy to replace and cheap. Disadvantage: temperature control is not so precision.

- copper sleeve type heat coil It is upgrade type of heater, and take place of market step by step. Advantage: it has good control of temperature, suitable for material and product which sensitive to temperature. Disadvantage: not easy to replace, need well educated worker and special tools to replace if it is damaged, and price is higher.

If your product is common houseware made in PP, spring type heat coil maybe not a bad choice, the best one is the suitable one.

Posted By Elaine

WERA MOLD

WhatsApp/Wechat: +86 18257612359

How valve gate help you save money?

For mold injection system, the most common way cold runner, hot runner open gate, hot runner valve gate, price from less to more, why still have client choose expensive valve gate? what’s advantage of valve gate

ABOUT CYCLE TIME

Cold runner Mold, Cold runner due to the runner size always thick, it takes time to cooling, so the cycle time always not short. especially for product with less weight, cold runner don’t have advantage.

Hot runner open gate Mold, even it is no need wait runner cooling, but it has limit of gate size, normally hot runner open gate size should be more than 2.5mm, otherwise, it will have tails, it cannot broke beautifully.

Hot runner valve gate Mold, there is no need wait runner cooling too, at the same time, the gate size limit is less, it can make the gate with 4 or even 6mm, because the valve pin can help cut the material beautifully. With bigger gate size, material is more easy to flow and can fill faster. It is also reason why some difficult flow material is better use valve gate, like for PC, PMMA material.

So after comparing, Hot runner valve gate can reach the shortest cycle time among these injection ways.

ABOUT COST

Even at beginning, you may pay more money on the mold, but actually, really is it the most expensive way? have you calculate real cost for whole production?

A. compare to cold runner, there is no need to cut gate manually, here save one labor cost, and there is no waste material for runner, save material cost too.

B. production cost, as explain in above, valve gate can reach shortest cycle time, in every hour, use the same machine, it make more pcs products, that means the cost for each product, with valve gate mold it is less.

of course, it needs accurate calculation to make comparison. For less quantity product, valve gate maybe not competitive, The more quantity produced, the more it saved.

WERA Mold will make proposal according to your situation and do calculation for you.

How should best mold looks like?

Sometimes, we will meet client who ask us to offer best mold, then how should best mold looks like ? what is best mold?

If client ask for an offer without any special requirement, many mold factory just quote per their experience, it depends what kind of clients they met before

I make an example base on pail mold

A pail mold with Master valve gate, German 1.2344 steel for core and cavity and mold core and cavity insert with Beryllium copper, is it best mold ? Yes, it is a good mold, you may use it for 5 years or even 10 years no, but the mold price is very high, does it can help you get what you invested back?

So in my mind, the best mold is the one most suitable for you, when you communicate with mold supplier, you need to tell your detail requirement, for example how many mold life do you expect to get from the mold, is it a new product you just want to test the market, or it is a repeat or improved product in your company to explore the market. Also the requirement on product is better to describe, how the surface you expected, with texture or mirror polish, in a word, the more detail you describe, the better offer supplier can offer to you.

We are looking forward to offer you best mold, welcome inquiry.

Medicine bottle cap Mold

Product Name

Medicine bottle cap

Mould information

Mold with 12 cavities, injection system with full hot runner and unscrewing system, use 250T injection machine for production, cycle time 16s

This cap mold core side is with 8 parts, need very precision dimension control, espcially for the neck sliders, neck slider steel need pay specially attention to it too, due to it moves each shot, it must very durable.

Only after ensure above parts, the mold unscrewing system can work well.

We are experienced making various cap mold, welcome inquiry and develop project together.

How to get short cycle time for spoon mold?

About the cycle time, a complete cycle is

Mold close — injection — cooling ( charging at the same time) — mold open — ejection — mold close

Normally, Machine dry cycle (mold open-ejection-mold close) take about 3 sec, injection will take about 2 sec. rest time is for cooling, spoon with 24 cav, about 8-10 sec for cooling is normal.

So in total cycle time 13-15 sec is normal cycle time. How to get shorter cycle time, it is not easy work, we need pay attention to follow points:

- from mold, cooling system design is key point, maximum cooling is mold designer need to consider.

- at the same time gate and runner size is important too. the most difficult for cooling area is runner and gate. the gate size should be controlled in a suitable size, to ensure easy injection but not take long time for cooling.

- Besides Mold, Cooling condition is important too, Chiller for sure is necessary in summer, in some countries with high temp. all the year, a good chiller should be prepared.

- From machine, dry cycle 3 sec is normal, if you want to get less cycle time, you can discuss with machine factory to see whether they can reduce dry cycle and injection time.

Above are some experience I get during mold testing, if you have any comments, or questions, welcome to discuss with us. and also welcome to WERA, let’s work together to get a good solution.

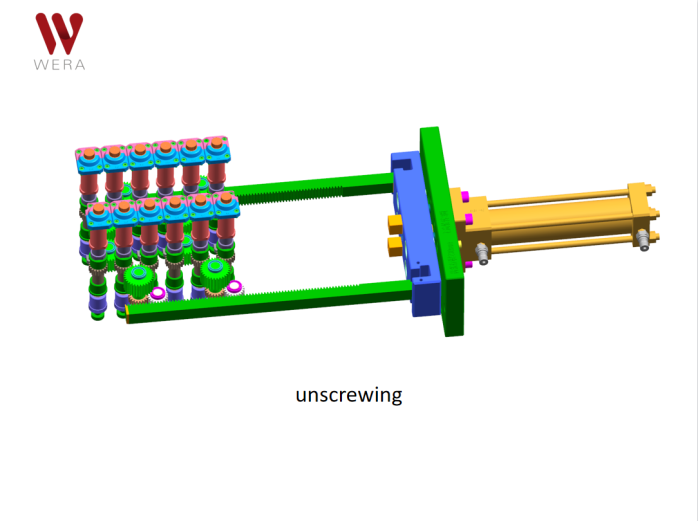

Fliptop Cap Mold with unscrewing system

As explain in last post, many products need unscrewing system, here is one case to share.

Product Name:

Fliptop cap

Mold information:

Mold with 8 cavities, injection system with semi hot runner, gate from the side. Mold production cycle time 16s.

On this mold, we use hydrocylinder system for unscrewing.

and for cooling system of this mold is perfect, to short the cycle time.

Fliptop cap mold cooling system

Mold testing video pls check in below link on Youtube: